Bitumen Introduction:

Bitumen is a black-colored and dough-shaped material used in moisture insulation and asphalt making. Bitumen has a variety of types, each of which has a special application. Bitumen is a derivative of oil

Penetration degree: Penetration grade test is used to determine bitumen hardness. In this test, a standard needle is penetrated from a 100-gram load in 5 seconds into the bitumen at a temperature of 25 degrees. The amount of penetration is called the tenth mm of penetration. The lower the penetration, the harder the bitumen.

The important application of bitumen is due to the presence of two important properties of this material, impermeability to water and high adhesion due to these features، The main consumption of bitumen is in the way of construction and insulation.

Bitumen types:

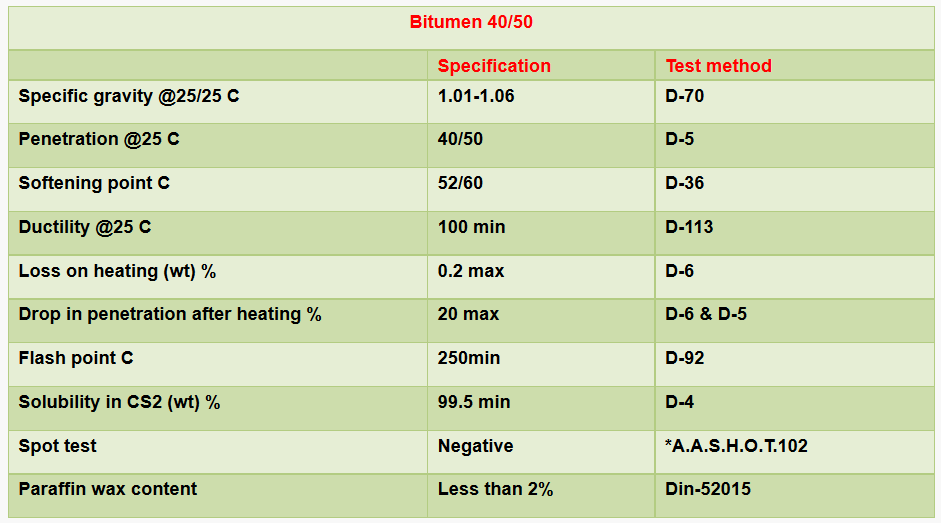

Bitumen 40-50:

Bitumen with a penetration degree of 40-50 is a type of bitumen produced in the oxidation process and baton. A baton is a byproduct of crude oil refining that is taken from the distillation tower in the vacuum of oil refineries. In the oxidation process, the baton is exposed to air and reacts with oxygen. This reaction causes bitumen to develop certain properties such as adhesion, durability and resistance to water and moisture.

The penetration degree of bitumen is represented by a double digit number. The first number shows the maximum penetration of bitumen at 25 degrees Celsius in millimeters. The second number shows the minimum penetration of bitumen at 25 degrees Celsius in millimeters. Therefore, bitumen with a penetration degree of 40-50 is bitumen, whose penetration is between 40 and 50 mm at 25 degrees Celsius.

Bitumen with a penetration degree of 40-50 is used in a variety of industries. The most important uses of this bitumen are:

*Road Correction: 50-40 bitumen used for asphalt production. Asphalt is made from a mixture of sand, sand and bitumen. Bitumen 40-50 is suitable for making asphalt due to its high adhesion and durability.

*Insulation: 50-40 bitumen is used to insulate structures against water and moisture. This bitumen is suitable for insulation due to its high sealing properties.

*Producing liquid bitumen: 50-40 bitumen is used to produce liquid bitumen such as 60-70 bitumen. Liquid bitumen is suitable for use at lower temperatures than solid bitumen.

In Iran, bitumen with a penetration rate of 40-50 is one of the most widely used types of industrial bitumen. This bitumen is used to produce asphalt on roads across the country. It is also used to insulate various structures such as tanks, canals and tunnels.

In the following, we will mention some features of bitumen with a penetration degree of 40-50:

*Paste: 50-40 bitumen has high adhesion. This makes the asphalt made with this bitumen a high adhesion to cobblestone and other materials.

*Durability: 50-40 beam has high durability. This makes the asphalt made with this bitumen resistant to wear, impact and other environmental factors.

*Water and humidity resistance:50-40 bitumen has high resistance to water and moisture. This makes the asphalt made with this bitumen resistant to water penetration and moisture.

* Viscosity: 50-40 bitumen has a moderate viscosity. This makes the asphalt made with this bitumen easily applicable.

Bitumen with a penetration grade of 40-50 is a quality bitumen with a variety of applications. This bitumen is used in various industries, including road construction, insulation and the production of liquid bitumen.

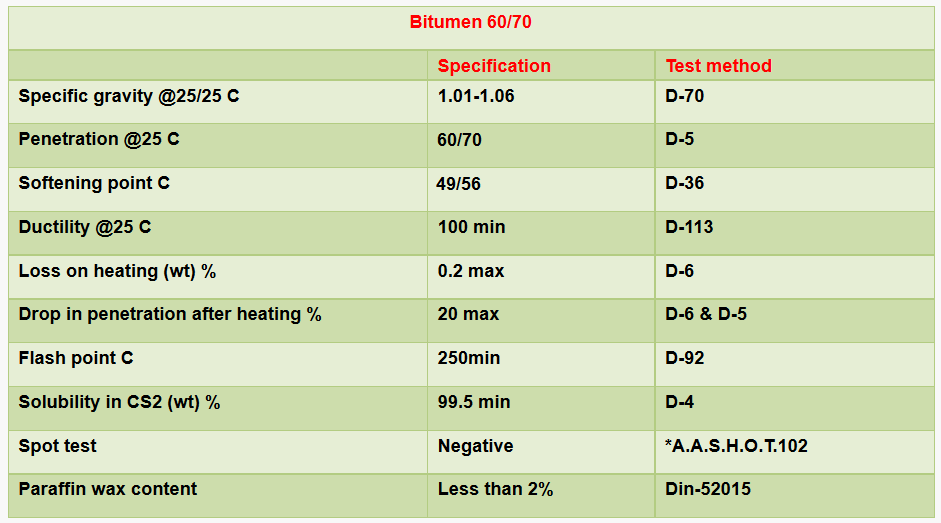

Bitumen 60-70:

Bitumen with a penetration degree of 60-70 is a type of bitumen produced in the oxidation process and baton. A baton is a byproduct of crude oil refining that is taken from the distillation tower in the vacuum of oil refineries. In the oxidation process, the baton is exposed to air and reacts with oxygen. This reaction causes bitumen to develop certain properties such as adhesion, durability and resistance to water and moisture.

The penetration degree of bitumen is represented by a double digit number. The first number shows the maximum penetration of bitumen at 25 degrees Celsius in millimeters. The second number shows the minimum penetration of bitumen at 25 degrees Celsius in millimeters. Therefore, bitumen with a penetration degree of 60-70 is bitumen whose penetration is between 60 and 70 mm at a temperature of 25 degrees Celsius.

Bitumen with a penetration degree of 60-70 is used in a variety of industries. The most important uses of this bitumen are:

* Road construction: 60-70 bitumen used for asphalt production. Asphalt is made from a mixture of sand, sand and bitumen. Bitumen 60-70 is suitable for making asphalt due to its high adhesion and durability.

*Insulation: 60-70 grades are used to insulate structures against water and moisture. This bitumen is suitable for insulation due to its high sealing properties.

*Production of liquid bitumen: 60-70 bitumen is used to produce liquid bitumen like 80-100 bitumen. Liquid bitumen is suitable for use at lower temperatures than solid bitumen.

In Iran, bitumen with a penetration rate of 60-70 is one of the most widely used types of industrial bitumen. This bitumen is used to produce asphalt on roads across the country. It is also used to insulate various structures such as tanks, canals and tunnels.

In the following, we will mention some of the features of bitumen with a penetration degree of 60-70:

*Paste: 60-70 bitumen has high adhesion. This makes the asphalt made with this bitumen a high adhesion to cobblestone and other materials.

*Durability: 60-70 bitumen has high durability. This makes the asphalt made with this bitumen resistant to wear, impact and other environmental factors.

*Water and humidity resistance: 60-70 bitumen has high resistance to water and moisture. This makes the asphalt made with this bitumen resistant to water penetration and moisture.

*Viscosity: 60-70 bitumen has high viscosity. This makes the asphalt made with this bitumen to have a high resistance to cracking.

Bitumen with a penetration grade of 60-70 is a quality bitumen with a variety of applications. This bitumen is used in various industries, including road construction, insulation and the production of liquid bitumen.

Compared with bitumen with a penetration grade of 40-50, bitumen with a penetration grade of 60-70 has higher adhesion, durability and resistance to water and moisture. It also has higher viscosity and can be used at lower temperatures. This makes 60-70 bitumen more suitable for applications that require higher strength and durability.

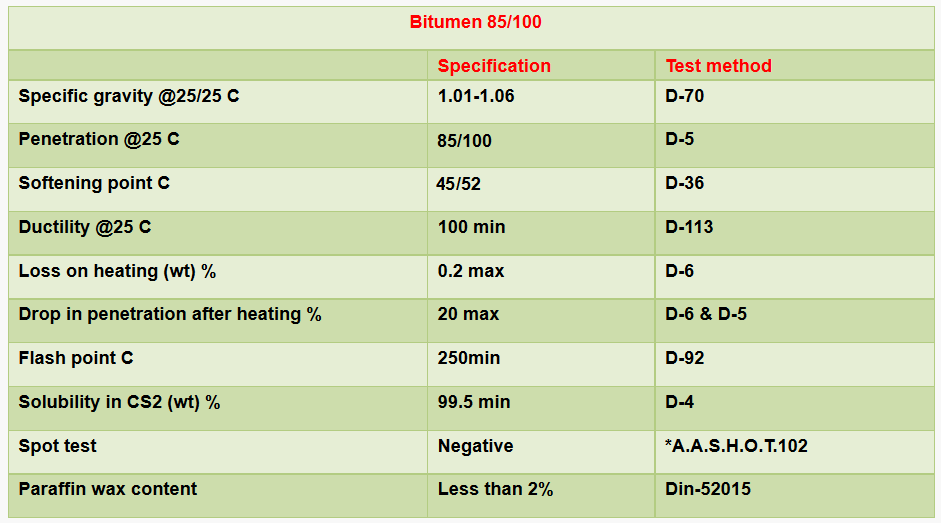

Bitumen 85-100:

Bitumen with a penetration degree of 85-100 is a type of bitumen produced in the oxidation process and baton. A baton is a byproduct of crude oil refining that is taken from the distillation tower in the vacuum of oil refineries. In the oxidation process, the baton is exposed to air and reacts with oxygen. This reaction causes bitumen to develop certain properties such as adhesion, durability and resistance to water and moisture.

The penetration degree of bitumen is represented by a double digit number. The first number shows the maximum penetration of bitumen at 25 degrees Celsius in millimeters. The second number shows the minimum penetration of bitumen at 25 degrees Celsius in millimeters. Therefore, bitumen with penetration degree of 85-100 is bitumen whose penetration at 25 degrees Celsius is between 85 and 100 mm.

Bitumen with a penetration degree of 85-100 is used in a variety of industries. The most important uses of this bitumen are:

*Road construction: 85-100 bitumen used to produce asphalt. Asphalt is made from a mixture of sand, sand and bitumen. Bitumen 85-100 is suitable for making asphalt due to its high adhesion and durability.

*Insulation: 85-100 coils are used to insulate structures against water and moisture. This bitumen is suitable for insulation due to its high sealing properties.

*Producing liquid bitumen: 85-100 bitumen is used to produce liquid bitumen such as 20-150 bitumen. Liquid bitumen is suitable for use at lower temperatures than solid bitumen.

In Iran, bitumen with a penetration degree of 85-100 is one of the types of industrial bitumen. This bitumen is used to produce asphalt on roads across the country. It is also used to insulate various structures such as tanks, canals and tunnels.

In the following, we will mention some of the features of bitumen with a penetration degree of 85-100:

*Paste: 85-100 bitumen has high adhesion. This makes the asphalt made with this bitumen a high adhesion to cobblestone and other materials.

*Durability: 85-100 bitumen has high durability. This makes the asphalt made with this bitumen resistant to wear, impact and other environmental factors.

*Water and humidity resistance: 85-100 bitumen has high resistance to water and moisture. This makes the asphalt made with this bitumen resistant to water penetration and moisture.

*Viscosity: 85-100 bitumen has a moderate viscosity. This makes the asphalt made with this bitumen easily applicable.

Bitumen with a penetration grade of 85-100 is a quality bitumen with a variety of applications. This bitumen is used in various industries, including road construction, insulation and the production of liquid bitumen.

Compared with bitumen with a penetration grade of 60-70, bitumen with a penetration grade of 85-100 has higher adhesion, durability and resistance to water and moisture. It also has higher viscosity and can be used at lower temperatures. This makes 85-100 bitumen more suitable for applications that require higher strength and durability.

However, bitumen with a penetration grade of 85-100 is more expensive than bitumen with a penetration grade of 60-70. Also, at higher temperatures, it is more prone to cracking.